ROTARY KILN COMBUSTION SYSTEMS COEN .

ROTARY KILN COMBUSTION SYSTEMS. ... cement, magnesite, kaolin, ... • Coal • Solvents • Woodwaste. Features of the Coen Kiln Burner

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

ROTARY KILN COMBUSTION SYSTEMS. ... cement, magnesite, kaolin, ... • Coal • Solvents • Woodwaste. Features of the Coen Kiln Burner

Raw Mix Designing for Coal as a Fuel in Cement Kiln as a Major Fuel and its Impact on Clinker Parameters ... local coal, in cement manufacturing, its formulation

Primarily for cement grinding plants in India, coal (generally of bituminous grade) is used in the slagdryer. The wet slag arrives at the stack on wagons from some ...

The cement kiln system is designed to ... such as coal are preferred for kiln ... 3 were measured leaving the stack of cement rotary kiln plants as ...

Cement Kiln CoProcessing (High Temperature Treatment) Page 3 of 11 Pesticides Treatment Technology Fact Sheet John Vijgen, International HCH and Pesticides Assoc

Coal is the fuel that undergoes least human intervention before use: it is burned in essentially the same condition in which it is dug from the ground.

Permit Summary – Addition of a Kiln and Related Operations . At CEMEX Facility in Clinchfield, GA . Project Description. This modification involves the construction ...

Coal cement Varying the mix of cement, sand and aggregate enables concrete to be used in a range of applications. Products can be designed, coloured and shaped to ...

Why Opposition to New Cement Plants Using Coal as Fuel Will Increase Emissions ... Half or more of the mercury going into a cement kiln can be from the coal.

CEMENT FACTORIES in Pakistan had been using ''furnace oil'' or ''natural gas'' as the fuel except those preindependent plants which used coal in the beginning.

carpet for coal in a cement kiln ... • Cofiring carpet with coal as a substitute fuel for cement kilns appears to be at least, environmentally neutral

Coal Kiln, Wholesale Various High Quality Coal Kiln Products from Global Coal Kiln Suppliers and Coal Kiln Factory,Importer,Exporter at

Alternative Fuels in Cement Manufacturing ... cement kiln systems as opposed to ... Cement production consumes approximately 120 kg of coal per tonne of cement. In

Find great deals on eBay for coal kiln. Shop with confidence.

Read "A theoretical analysis on combustion intensification for blended coal in rotary cement kiln, Fuel" on DeepDyve, the largest online rental service for scholarly ...

This means that when TDF replaces coal in a portland cement kiln—for example, when scrap tires are used to heat the precalciner vessel instead of coal—less CO

DOE/NETL2002/1163 Cement Kiln Flue Gas Recovery Scrubber Project: A DOE Assessment November 2001 Department of Energy National Energy Technology .

coal ash properties impact on clinker quality. dear ted. is there any good impact when we use lignite as a fuel instead of other solid fuels with low ash content.

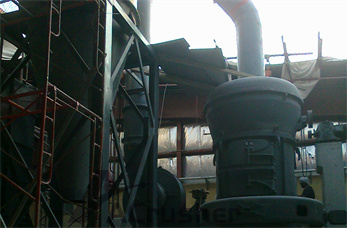

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, ... Coal Vertical Roller ... Cement Rotary Kiln ...

The utilisation of coal in the cement and concrete industries takes three basic forms: a fuel in the production of cement clinker, produced by burning

Coal fineness has a direct relationship with its reactivity. Hence in the cement plant a special significance has been given to the milling behavior of coal.

Official FullText Publication: Modeling coal combustion in a rotary cement kiln on ResearchGate, the professional network for scientists.

The cement kiln uses ... PSL has developed a 3D coupled computational model to predict the flow and heat transfer in cement kilns. ... combustion of coke and coal, ...

Cement Kiln Recycling Coalition member companies include most major US cement manufactures who use wastederived fuels in cement kilns

WhatsApp)

WhatsApp)